3D printing seems to be everywhere these days, used to create everything from handguns to headphones. But what does it really take to get started: How much does it cost, how difficult is it to use, and how do you actually get your hands on a 3D printer?

Last week, a law student from the University of Texas in Austin leased a printer made by Stratasys, the uPrint SE 3D. He wanted it to create a prototype of a 3D-printable handgun. Turns out Stratasys didn‘t much like that idea, so it took back the printer, saying the student’s lack of a firearms manufacturer‘s license made what he wanted to do illegal. (For more on this topic, see John Paul Titlow’s story on How 3D Printing Is Inflaming The Gun Control Debate.)

A Reuters story?, meanwhile, found that the European Union is asking member countries to invest in 3D printing technology to speed up and raise manufacturing output.

So just how hard is it for an average person get access to one and actually start making things?

Why would you want a 3D printer, anyway? Because you can make just about anything with one. From utensils to iphone cases and apparently weaponry, 3D printers can create just about anything your imagination (and a quality computer-aided drafting and design - CADD - software) can create. It‘s like an Easy Bake Oven for computer geeks.

How Much Do 3D Printers Cost?

Until fairly recently, 3D printers were available only to major industries to create prototypes or cheap and functional products. Now, anyone can get do-it-yourself 3D printing kits from sites like MakerBot?for about $1,500.

If you want a more sophisticated machine, though, you’ll probably have to deal with a sales rep. That‘s how Stratasys, the company currently embattled with the law student, sell its machines. The company offers leasing programs for its printers that range from $185/month to $299/month. If you wanted to buy one flat out with no leasing, you’d have to pony up about $10,000. Just this year, CNET reviewed three different types of consumer-available 3D printers that you can log on and buy, no sales rep needed, with prices ranging from $500 to $2,000.

If you don‘t have a printer of your own, you can still get 3D models printed out through a service, kind of like a 3D version of FedEx Kinkos. Shapeways, a startup in New York, offers this service: just upload your model idea to the site, choose your materials, and Shapeways will give you a pricing estimate. Within a few weeks, the company will print it out and ship it to you. For particularly creative users who are good with software, the company offers product ideas that you can custom design and build.

How Do They Work?

The process these printers create models is fairly simple. Using a design from a CADD program, they turn 3D images into a series of thin, horizontal, virtual layers until a virtual version of what is to eventually be printed is modeled on screen. These CADD designs can be found online, or created by scanning a physical object. Designing complex objects from scratch requires a certain amount of skill and training.

Depending on the machine and the project, different materials can be used to construct the model. For the cheaper machines, plastic or resin is commonly used, while more industrial projects can employ powered metals, alloys or polycarbonate materials. There are even food-grade printers that use chocolate and sugar to create edible models.

Layer by layer, the machine lays the image out on to a heated platform. 3D systems at home printer Cubeincludes a platform glue that keeps the base of the project steady during printer and washes off with water. Once it’s printed and cooled, you‘ll have a tactile version of something that used to just occupy space in your head.

If you are itching to print something, but are not particularly creative, a site from Makerbot, Thingiverse can offer up a few ideas. The open-source community has instructions on how to print your own products (like thesefunctional headphones that made tech bloggers drool a few days ago) and provides an overall glimpse into the world of 3D printing and creativity.

自動翻譯僅供參考

操作一臺3D打印機究竟有多難

3D打印似乎無處不在這些日子里,用來創造一切從手槍到耳機。但什么是它真正需要上手:需要多少成本,有多難用,你怎么真正得到你的手在3D打印機嗎?

上周,來自德克薩斯大學的一名法律系學生租借了由UpPress SE 3D制作的Stratasys的打印機。他希望它能制造出3D打印手槍的原型。事實證明,Stratasys不太喜歡這個想法,所以他收回了打印機,說學生缺乏槍支生產許可證使他想做的違法。(關于這個話題,請參閱John Paul Titlow關于3D打印是如何引發槍支控制爭論的故事。)路透社報道,同時,發現歐盟正在要求成員國投資3D打印技術,加快和提高制造業產出。

那么,這是多么艱難的普通人可以訪問之一,真正開始做的事情?

為什么你會希望有一個3D打印機,反正?因為你可以只是一個東西。從餐具到iPhone的情況下,顯然武器,3D打印機可以創建幾乎任何你的想象力(和質量計算機輔助繪圖和設計 - CADD - 軟件)可以創造。這就像一個簡易烤爐的計算機愛好者。

做了多少3D打印機成本?

直到最近,3D打印機只提供給各大產業創造原型或便宜,功能性產品。現在,任何人都可以從網站,如MakerBot為1500美元獲得做自己動手3D打印套件。

如果你想要一個更復雜的機器,不過,你可能不得不面對一個銷售代表。這是Stratasys公司,目前正在與法律系學生四面楚歌的公司,如何出售其機器。該公司提供的租賃方案,其打印機產品,范圍從$ 185 /月至299美元/月。如果你想購買一個單位出來,沒有租賃,你必須從腰包里掏出1萬美元。就在今年,CNET審查三種不同類型的消費者提供3D打印機,你可以登錄并購買,不需要銷售代表,價格從500美元到2,000元。

如果你沒有自己的打印機,你仍然可以得到打印出來,通過服務,有點像3D版聯邦快遞以Kinkos的3D模型。 Shapeways,在紐約啟動,提供這種服務:剛才你的模型的想法上傳到網站,選擇你的材料和Shapeways會給你一個價格的估計。在幾周之內,該公司將它打印出來,并將其發送給您。對于特別創意的用戶誰是很好用的軟件,該公司提供的產品的想法,你可以自定義的設計和建造。

它們如何工作?

這些打印機創建模型的過程相當簡單。使用設計從CADD程序,他們把3D圖像轉換為一系列輕薄,臥式,虛擬層,直到什么是最終打印是仿照屏幕上的虛擬版本。這些CADD設計可以在網上找到,或通過掃描物理對象創建。從頭設計復雜的對象,需要一定的技巧和培訓。

根據不同的機器和該項目上,不同的材料可以用來構建模型。對于便宜的機器,塑料或樹脂常用,而更多的工業項目可以采用電動金屬,合金或聚碳酸酯材料。甚至有使用巧克力和糖打造食用型號食品級打印機。

一層一層,機器勾畫出來的圖像上加熱的平臺。在家用打印機3D系統Cubeincludes一個平臺,膠水,保持了穩定的項目的基本打印機中,并用清水洗去。一旦它的印刷和冷卻,你就會有一些以前只是占用空間,在你的頭上觸覺版本。

如果你渴望打印的東西,但不是特別有創意,從Makerbot網站,Thingiverse可提供高達一些想法。開源社區對如何打印自己的產品(如,使得高科技博客流口水,前幾天thesefunctional耳機)的指令,并提供一個整體一窺3D打印和創造力的世界。

-

3D打印

+關注

關注

26文章

3561瀏覽量

109451

發布評論請先 登錄

相關推薦

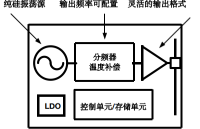

有源晶振在3D打印機應用方案

領麥微紅外測溫傳感器在小型光敏3D打印機中的創新應用

應用在3D打印機的BD系列金屬連接器

Klipper固件的打印機可以插卡打印嗎?

2024年含直線電機3D打印機在內共出口182.9萬臺

UltiMaker正式推出了工業級3D打印機—UltiMaker Factor 4

YXC晶振 32.768KHz石英振蕩器,封裝3225,應用于3D打印機

操作一臺3D打印機究竟有多難

操作一臺3D打印機究竟有多難

評論