| Rating | Automotive |

| Architecture | Integrated FET |

| Control topology | Sensorless, Sinusoidal |

| Control interface | 1xPWM, Analog, Serial |

| Vs (Min) (V) | 6.2 |

| Vs ABS (Max) (V) | 45 |

- Qualified for automotive applications

- AEC-Q100 qualified with the following results:

- Device temperature grade 1: –40°C to 125°C ambient operating temperature range

- Device HBM ESD classification level 1C

- Device CDM ESD classification level C4A

- Operation voltage range:

- Motor operation, 6.2 V to 28 V

- Register setting preserved, 4.5 V to 45 V

- Supports load dump voltage up to 45 V

- Total driver H + L rDS(on)

- 250 mΩ at TA = 25°C

- 325 mΩ at TA = 125°C

- Drive current: 2-A continuous winding current (3-A Peak)

- Configurable output PWM slew rate and frequency for EMI management

- Sensorless proprietary Back Electromotive Force (BEMF) control scheme (no need of hall sensors)

- Continuous sinusoidal 180° commutation

- Initial position-detect algorithm to avoid back spin during start-up

- No external sense resistor required

- Flexible user interface options:

- I2C interface: access registers for command and feedback

- Dedicated SPEED pin: accepts either analog or PWM input

- Dedicated FG pin: provides TACH feedback

- Spin-up profile can be customized with EEPROM

- Forward-reverse control with DIR pin

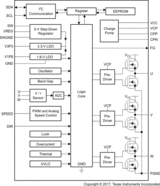

- Integrated buck converter to efficiently provide 5?V and 3.3-V LDOs for internal and external circuits

- Supply current 8.5 mA with standby version (DRV10983SQ)

- Supply current of 48 μA with sleep version (DRV10983Q)

- Protection features

- Overcurrent protection (protection for phase-to-phase, phase-to-GND and phase-to-vCC shorts

- Lock detection

- Anti-Voltage Surge (AVS) protection

- UVLO protection

- Thermal shutdown protection

- Thermally enhanced package

The DRV10983-Q1 device is a 3-phase sensorless motor driver with integrated power MOSFETs, which can provide continuous drive current up to 2 A. The device is specifically designed for cost-sensitive, low-noise, low-external-component-count fan and pump applications.

The DRV10983-Q1 device preserves register setting down to 4.5 V and delivers current to the motor with supply voltage as low as 6.2 V. If the power supply voltage is higher than 28 V, the device stops driving the motor and protects the DRV10983-Q1 circuitry. This function is able to handle a load dump condition up to 45 V.

TI provides DRV10983-Q1 tuning Guide for quick setup and tuning of the device for optimal performance.

- Device Options:

- DRV10983Q: Sleep Version

- DRV10983SQ: Standby Version

The DRV10983-Q1 device uses a proprietary sensorless control scheme to provide continuous sinusoidal drive, which significantly reduces the pure tone acoustics that typically occur as a result of commutation. The interface to the device is designed to be simple and flexible. The motor can be controlled directly through PWM, analog, or I2C inputs. Motor speed feedback is available through both the FG pin and the I2C interface simultaneously.

The DRV10983-Q1 device features an integrated buck regulator to step down the supply voltage efficiently to 5 V for powering both internal and external circuits. The 3.3-V LDO also may be used to provide power for external circuits. The device is available in either a sleep mode or a standby mode version to conserve power when the motor is not running. The standby mode (8.5 mA) version (DRV10983SQ) leaves the regulator running and the sleep mode (48 μA) version (DRV10983Q) shuts the regulator off. Use the standby mode version in applications where the regulator is used to power an external microcontroller. Throughout this data sheet, the DRV10983-Q1 part number is used for both devices for example DRV10983Q (sleep version) and DRV10983SQ (standby version), except for specific discussions of sleep vs standby functionality.

An I2C interface allows the user to reprogram specific motor parameters in registers and to program the EEPROM to help optimize the performance for a given application. The DRV10983-Q1 device is available in a thermally-efficient HTSSOP, 24-pin package with an exposed thermal pad. The operating ambient temperature is specified from –40°C to 125°C.